Technological Frontier Layered Polydimethylsiloxane Polyurethane (PDMS-PU) Nanocomposites for Marine Applications

A novel superhydrophobic nanocomposite material based on polydimethylsiloxane polyurethane (PDMS-PU) and graphene/tungsten disulfide exhibits strong anti biological adhesion, corrosion resistance, and mechanical durability without the use of biocides.

In a recent study published in "Progress in Organic Coatings" (March 2025, Volume 200), researchers developed non-toxic superhydrophobic nanocomposite coatings for marine anti biofouling applications. This new material is based on polydimethylsiloxane polyurethane (PDMS-PU) and filled with graphene oxide (GO) nanosheets loaded with tungsten disulfide (WS2) nanorods. The GO-WS2 hybrid structure can enhance surface roughness and dispersibility, thereby improving hydrophobicity and anti biological adhesion ability.

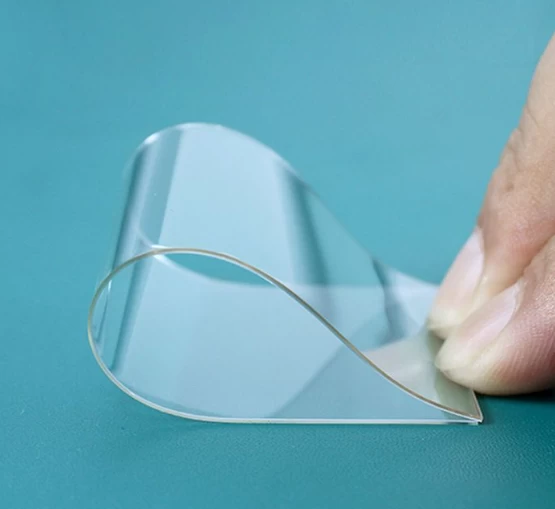

The research team used an improved Hummers method and a surfactant assisted hydrothermal method to prepare nano hybrid materials. Then, the nano fillers were ultrasonically blended into the polymer matrix through ultrasonic oscillation, resulting in the uniform distribution of GO-WS2 particles in the coating and the formation of layered micro/nano rough surfaces. The nanocomposite material containing 2.5 wt% filler exhibits a 150 ° water contact angle, 20.4mN/m surface free energy, and excellent superhydrophobicity due to the structured surface trapping air.

Excellent anti attachment and anti-corrosion performance under biological stress

Researchers conducted a 30 day attachment test on four common marine microorganisms (Burkholderia rhizobia, Pseudomonas fluorescens, Aspergillus fumigatus, and Candida albicans) in a laboratory environment. The results showed that PDMS-PU/GO-WS2 nanocomposites containing 2.5 wt% filler exhibited the lowest microbial adhesion rate and surface degradation rate, with better performance than other formulations.

In addition to its biological protective properties, this coating also has high mechanical strength and corrosion resistance, making it suitable for long-term use in harsh marine environments. Its non fungicidal properties provide an environmentally friendly alternative to traditional anti biofouling strategies that rely on toxic additives.