-

- Release on2025-03-04

- Excellent foreign trade salespersons need to possess various abilities such as language, communication, market analysis, and negotiation, as well as good professional ethics and stress resistance, in order to stand out in the fiercely competitive market....Read More>>

-

- Release on2025-02-21

- Production and Material Control play a crucial role in foreign trade export companies, especially in the links involving production, supply chain management, and order delivery....Read More>>

-

- Release on2025-02-12

- Facilities: Operates a 2,800 m² office in Xiamen’s Wuyuan Bay and a production base in Tong’an Graphene Industrial Park. Employee Culture: Emphasizes values like "Customer First" and "Team Collaboration," offering benefits such as insurance, training, and annual events. The company combines R&D excellence with sustainable practices, aiming to lead in green, health-focused material solutions globally....Read More>>

-

- Release on2024-09-04

- The theme of the birthday party is blue, white, and silver....Read More>>

-

- Release on2022-07-22

- It is the trend of the times that the national strength is enhanced, the culture is self-sufficient, and the rise of domestic products. According to "Baidu 2021 Guochao Pride Search Big Data", the attention of Guochao has increased by 528% in the past ten years. In the past five years, the proportion of Chinese brand search popularity has increased from 45% to 75%, which is three times that of overseas brands. In 2021, the sales of domestic brands of Douyin e-commerce will increase by 667% year-on-year; among the top 10 brands in JD.com's turnover, the proportion of domestic brands will increase from 60% in 2017 to 90% in 2021....Read More>>

-

- Release on2022-07-12

- Global Polyurethane Network News: On October 27th, the 2017 China Isocyanate-CASE Industry Chain Status and Development Trend Summit Forum, hosted by Speedy Consulting and co-organized by Global Polyurethane Network, came to an end at Days Hotel Frontier in Suzhou....Read More>>

-

- Release on2022-07-01

- Through the EU ISCC certification (international sustainable development and carbon certification), the use of fossil raw materials has been reduced by 99.9% • Physical and chemical properties are exactly the same as traditional petroleum-based products, which can be directly replaced by customers • Used as raw material for adhesives and sealants or as a liquid rubber additive in tire production Evonik launches POLYVEST® eCO, a new range of sustainable bio-based liquid polybutadiene products. This innovative product line uses sustainable butadiene in its production, reducing the use of fossil feedstocks by 99.9%. "There is a growing demand for efficient, environmentally friendly and sustainable products," said Dr. Jürgen Herwig, head of Evonik's POLYVEST® global business. "By developing POLYVEST® eCO, we want to support the transition to a circular and bioeconomy." Adoption The final product of POLYVEST® eCO is physicochemically identical to petroleum-based products. Sara Liébana Vi?, Global Technical Marketing Director, Evonik Reactive Sealants "For the customer, the biggest advantage of the new product is that there is no need to adjust the existing formulation," says Dr. As. "It's almost the most convenient option for reducing CO2 emissions." Evonik's POLYVEST® production facility in Marr, Germany received ISCC PLUS certification (International Sustainability and Carbon Certification) earlier this year. This certification shows that the production process of the product is based on the mass balance method and verifies that the site operates in compliance with strict sustainable guidelines in terms of social responsibility, environmental standards and more. POLYVEST® eCO can be used as a raw material for adhesives and sealants in the automotive, electronics, construction and other industries, and as a rubber additive in tire production...Read More>>

-

- Release on2022-05-16

- The BMW Group is the first car manufacturer to trust more sustainable automotive OEM coatings certified according to BASF's biomass balance approach. The BMW Group has chosen to use BASF Paint's CathoGuard® 800 ReSource e-coat at its plants in Leipzig, Germany and Rosslyn, South Africa, and iGloss® matt ReSource varnish throughout Europe. Using these more sustainable versions of the product in automotive coatings could result in the avoidance of about 40% of CO2 per coat; this will allow factories to reduce CO2 emissions by more than 15,000 tons by 2030....Read More>>

-

- Release on2022-04-25

- Covestro is expanding the production capacity of its Platilon® family of thermoplastic polyurethane (TPU) films, as well as the associated infrastructure and logistics. To this end, the company is investing less than 50 million euros in its German Center of Excellence for the above-mentioned films in Bomlitz, Lower Saxony, Germany....Read More>>

-

- Release on2022-01-08

- ...Read More>>

-

- Release on2021-10-22

- Finehope Company...Read More>>

-

- Release on2021-10-22

- Company activity of Mid-Autumn...Read More>>

- Certifications

-

- Subscribe

-

Get email updates on new products

- NEWSMore>>

-

- Application of Polyurethane (PU) in Taekwondo Head Protection

- Evonik showcased its innovative solutions based on renewable raw materials

- Global polyurethane market research: compound annual growth rate (CAGR) of 3.5%

- GRASS Group from Germany and GARDENA from Italy jointly released a new generation of garden lawn mower seats

- The Development Status of Global Polyurethane Synthetic Leather

- The progress of polyurethane (PU) in environmental protection

- Deere&Company, the world's largest manufacturer of riding agricultural and forestry lawn mowers, is based in the United States

- BASF and Maichi Innovative Additive Solutions establish strategic partnership

- The company's main products are ecological functional polyurethane synthetic leather and composite materials, which are applied in fields such as football

- Technological Frontier Layered Polydimethylsiloxane Polyurethane (PDMS-PU) Nanocomposites for Marine Applications

- Contact Us

-

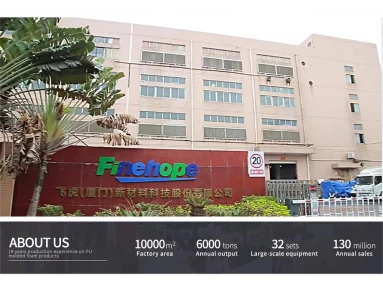

Finehope has a complete management mechanism. Since 2006, it has passed the ISO9001 quality management system audit and certification of the Swiss SGS Group for many times; in 2021, it passed the IATF16949:2016 automotive quality management system certification.

Finehope has a wealth of experience in cooperation with Fortune 500 companies, Caterpillar construction machinery in the United States, and STIGA, the largest garden machinery group in Europe, the world\'s largest second-hand forklift and forklift parts company, TVH, and the world\'s third Experience in cooperating with world-renowned companies such as the fitness sports brand STARTRAC.Contact Now