What does PMC means in Chinese factory?

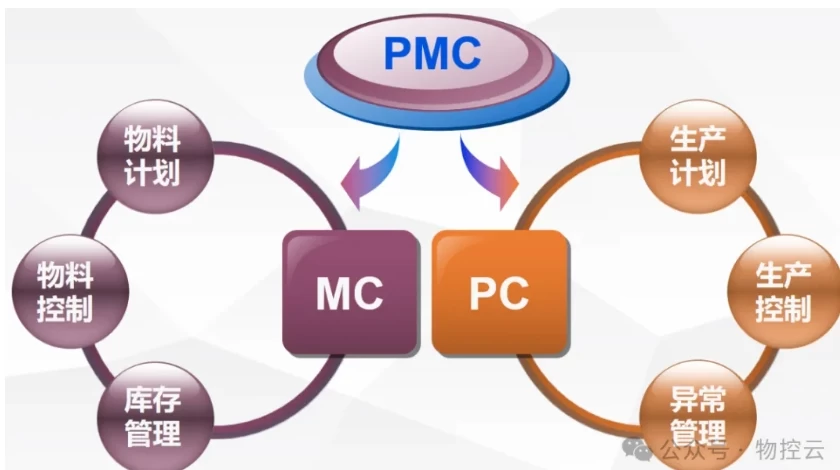

PMC stands for Production Material Control, which stands for Production and Material Control.

It mainly involves two aspects:

One is Production and Material Control (MC), responsible for material planning, procurement, material scheduling, material control, etc;

The second is capacity analysis, which involves managing production plans and schedules.

The responsibilities of PMC also include preparing production plans and orders, organizing production, coordinating the work progress of various departments, developing and supervising the implementation of material requirement plans, calculating and improving supplier delivery times, as well as managing materials waiting, returning, replenishing, and borrowing during the production process. In addition, PMC also involves the establishment and improvement of warehouse management systems, as well as the prevention and handling of stagnant materials.

The practice of PMC includes inventory forecasting methods, control methods for material purchase batches with different demand characteristics (such as JTT, EOQ, LOT FO LOT control methods), material inventory control methods (such as ABC control method, quantitative control method, periodic control method, coefficient of variation control method), management of dead and off balance sheet materials, material packaging and workstation equipment planning, spare parts management, and other aspects. Through these practices, PMC aims to optimize production processes, improve material efficiency, reduce inventory costs, and ensure smooth production. Overall, PMC is a comprehensive management field aimed at improving production efficiency, reducing production costs, and ensuring product quality and production safety through effective material and production planning control.